T1 / T3 Crankshaft Main Bearing Set, STD, STD, STD

Classic Aircooled VW Crank Shaft Bearings parts by Limebug

T1 / T3 Crankshaft Main Bearing Set, Standard, Standard, Standard

How to measure you Aircooled VW Main Bearing Set

Thrust

Theory behind thrust wear:

So you may have heard people in the scene referring to 'End Float' and engines being worn out with excessive play. This is all based around the main bearing wearing over a long period and developing a more 'Sloppy' fit in the journal the bearing sits in.

A number of ways to check this is if you pull and push on your pulley in situe you should feel a small amount of play between 0.065 and 0.125mm. Wear limit is 0.15mm where the case and bearings require machining and replacing.

The solution is to this is to have a machinist carry out a thrust cut on the case to re-define the collar to a set value meaning you can re-install a new slightly oversize bearing to give a tight as original tolerance.

Where to measure:

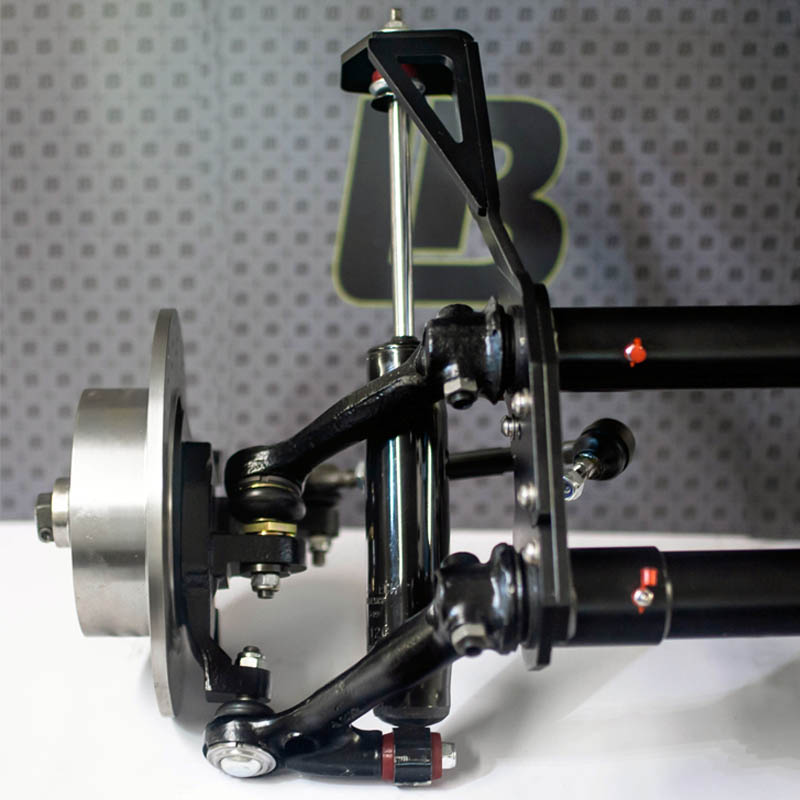

if you look at the diagram above you can see the distance between the two shoulders. Look to the side where the dowel hole can be found, the sidewall on this on a standard bearing will be as standard will be 2.5mm, for oversize see below:

– 2.5mm Shoulder (Standard Thrust) Choose STD in Options under 'Thrust'

– 3.5mm Shoulder (1mm Oversize) Choose 1mm Thrust in Options under 'Thrust'

– 4.5mm Shoulder (2mm Oversize) Choose 2mm Thrust in Options under 'Thrust'

If you exceed 2mm of thrust in terms of most suppliers of bearings the case is scrap and cannot be re-machined again.

Case Oversize

Theory behind case wear:

The surfaces which the bearings sit on wear over time despite in theory being stationary with the combination of the driving radial gear between the camshaft and the crankshaft and continuous rotational forces, the bearing can work loose on the dowels and begin to chew into the bearing mounting faces. This is most noticeable normal on the main bearing (Pictured above with the two shoulders).

The only solution to this is to have a line bore which will oversize the bearing mounting surfaces to a fixed integer and reset the tolerances.

Where to measure:

If you take your bearing and measure the OD between the two shoulders on the main bearing the measurement as standard should be 65mm, for oversize see below:

– 65mm Outside Diameter (Standard Case) Choose STD in Options under 'Case Size'

– 65.5mm Outside Diameter (Oversize on Case) Choose +0.50mm in Options under 'Case Size'

– 66mm Outside Diameter (Oversize on Case) Choose +1.00mm in Options under 'Case Size'

– 66.5mm Outside Diameter (Oversize on Case) Choose +1.50mm in Options under 'Case Size'

– 67mm Outside Diameter (Oversize on Case) Choose +2.00mm in Options under 'Case Size'

Crank Size

Theory Behind Case Wear:

The surfaces which the crankshaft runs on is subject to constant heat and friction. Aircooled engines operate at very high temperatures and over time these surfaces do wear. Another common reason to crankshafts wearing into the bearings is oil thinning, cause by fuel ingress into the oil, a common cause of this is engines which sit for long periods of time without being run and/ or not maintaining or checking oil levels and consistency.

The solution in most cases of crank wear is a light crank polish, in severe cases the crank can be re-ground to a stepped increment, and use a matched bearing to suit.

Where to measure:

As standard a VW T1 crankshaft journal for the main bearing should be 55mm, for oversize see below:

– 55mm Inside Diameter (Standard Crank) Choose STD in Options under 'Crank Size'

– 54.75mm Inside Diameter (Oversize on Crank) Choose +0.25mm in Options under 'Crank Size'

– 54.50mm Inside Diameter (Oversize on Crank) Choose +0.50mm in Options under 'Crank Size'

– 54.25mm Inside Diameter (Oversize on Crank) Choose +0.75mm in Options under 'Crank Size'

– 54.00mm Inside Diameter (Oversize on Crank) Choose +1.00mm in Options under 'Crank Size'

OE Reference: 111-198-461

SKU: 010050010