Table of Contents

ToggleThe History

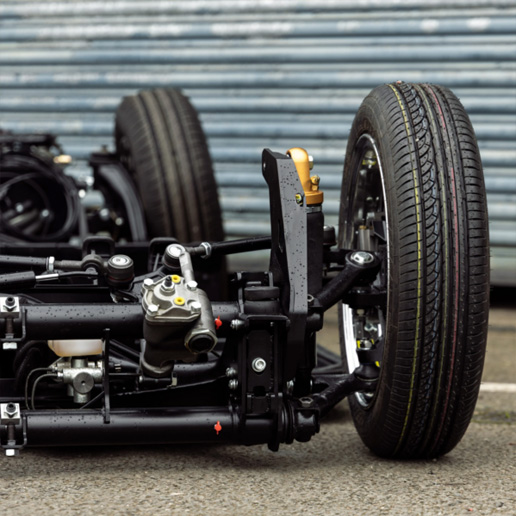

As of recent years, Air Ride has been a heavily discussed topic among Aircooled Enthuasiasts. From the sketchy weld-in kits made by some in their home-garages, to the original 2-way kits which severely affected handling, the concept of Air Suspension often recieves a bad reputation. In 2014, we decided that enough was enough. With the release of our Gen I kit, we allowed Aircooled owners to install a bolt-on kit, designed for an easy install, with no-need to weld or cut up the original pan/chassis. Although being one of the first bolt-on kits available on the market, we wanted to spend more time enhancing our design. We therfore took a further 12 months, delving into each part of our kit and adding extra features and designs to create the ultimate bolt-on. After hundreds of hours of hardwork in the workshop, the Gen II Kit was born.

What We Did

Air Shocks:

Although throughout the years Air Shocks for the Aircooled format have been readily available, we felt that these off the shelf bags needed improvement. With older generation air shocks, there are two main issues. Firstly, the ride quality over bumps and holes is poor. This is caused by the large footprint of the lower part of the bag. When the weight of the car pushes against the shock, the air has nowhere to go, leading to a harsh impact, a little like bottoming out a shock. The secondary problem we found with these shocks was lift. Due to being designed for level-loading setups on towing vehicles, these shocks have a small air capacity. Lifting the entire front end of a vehicle without assistance from leaf springs etc, makes this a challenge. Although this widely-chosen option is a cheap way to air out your vehicle, it is by no means designed for this purpose.

To amend these issues and provide our customers with an Air Shock designed with Aircooled in-mind, we introduce the MOA range. We now have models available to work on all years/platforms of Aircooled Volkswagen. The MOA430 comes in a coilover-style setup, with a tapered bag/body. This allows the shock to lift to high pressures, without expanding in size. To ensure this design is never at risk of over-inflation, we added a roll-over design to the lower connecting section of the shock. To further help the shocks clearance, we spent a long time developing the head/tail shape. The latest design available will now clear all factory suspension parts, without the need to adapt the OE fixings. To finalise these areas of the shock, the mounting points contain spherical bearings. These bearings fit all OE fixings, with sound deadening – No one likes rattly suspension. The final piece of the MOA range which makes it unique to other air shocks on the market, is the narrow-bore piston. This piston provides the shock with lateral stiffness beyond what would be needed to lift the vehicle, which allows lift/drop to be accurate and smooth.

Shock Relocators:

The concept of a shock relocator is to re-position the lower mounting point, to reduce lifting pressure. In past designs, off-the-shelf products have done this by about 15/20mm. Although this helped with riding pressures, we felt thatr the design could be improved further. By measuring the desired mounting locations on one of our development vehicles, we managed to re-design the concept to work a lot more effectively. Utilising our relocators, your shock can now sit 65mm further backwards (that’s 45mm more than previous designs!). In addition to this, we developed the shape of our relocator to move the shock outwards. This helps your shock to sit vertically straight when mounted to a narrowed beam, further improving lifting pressures. Furthermore, moving the lower shock outwards helps to prevent fouling on the inner wing of Link Pin vehicles.

Shock Towers:

On original Narrowed Beam Kits available on the market, Shock Towers often caused compatibility issues on many vehicles. From the harsh right angled shape of the tower fouling on other suspension parts, to the laser cut top shock mount holes, we felt we could improve the idea. As some of you may already know, our beam kits are modular. This means that our shock towers/skid ends can be transferred from beam to beam. Why buy a new beam for a different aircooled platform when you can just change shock towers? Alongside this, we spent time re-designing the shape of our towers to work with all years/width beams. Moving away from the sharp angles of original style shock towers, we have made the transition from upper to lower tower angular, allowing more room around the beam. This allows all year cars to work without rubbing, plus prevents bag rub for those running other aftermarket bags. In-order to keep the kink in our towers strong, we added a laser cut gusset along the outer edge. Welded into place by our state-of-the-art Robot Welder, this piece adds an enormous amount of strength, preventing any sort of flex the tower may have to withstand. In the upper centile of the Jawbreaker series Shock Towers, we have added a small slot, ideal for poking airline through when aseembling your air suspension managment. To conclude the additional features we’ve added to our Shock Tower design, a thick cast OE thread replaces lazy empty holes found in old examples on the market. This casting adds a substantial amount of strength to the pin – With our towers the top bolt would need to completely shear to come loose.

Skid Ends:

Due to the customisable design of our Gen II Beams, you have the option to choose your desired Skid End setup. This allows your beam to keep-up with the change of requirements your build poses, without the financial burdens. Furthermore, for those choosing to drag their pan across the road surface, skid-ends are easily replacable; allowing you to keep your beam tube protected at all times.

As standard, our beams come with a OE style piece. However, we also offer extra add-ons to make your aircooled ownership easier. A popular option with our existing customers is the Tow Eye. This piece comes with a tow hook in a strong mounting point, ideal for those dreaded breakdowns. A secondary add-on we offer is the Airlift 3H height sensor mount skid ends. These ends come with the extra cutouts/mounting blocks to allow compatibility with height sensors. For more info on Airlift 3H and how it can help maintain the underside of your vehicle, feel free to get in contact with a member of our team. This option is also available with a Towing eye!

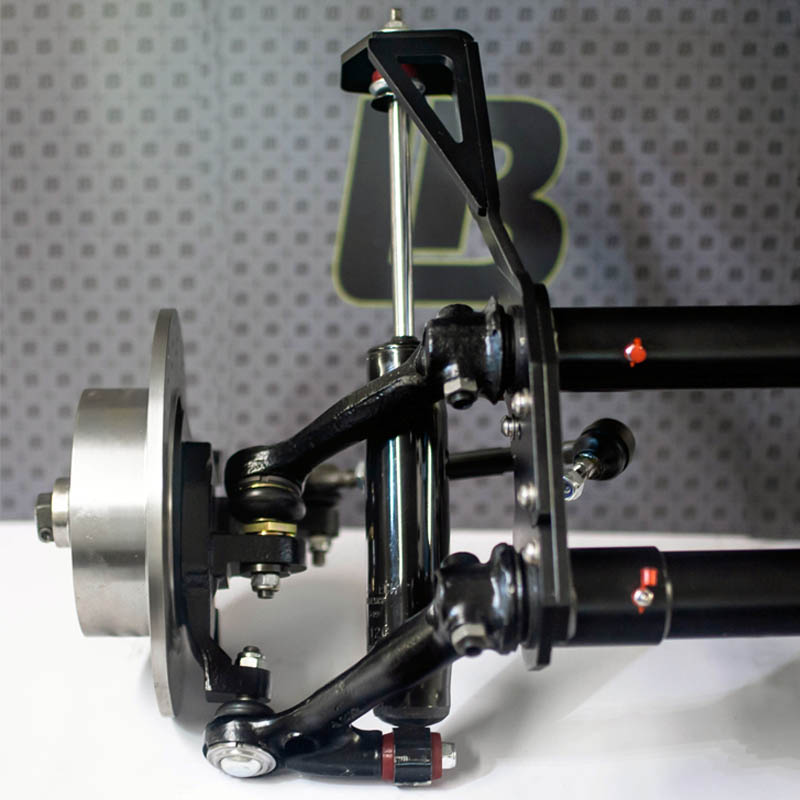

Through Rods:

Original Through Rod designs work with a long tubular thread going through the beam, fixed into place by nuts, which were tightened on either side of the Trailing Arms. The common problem with this design: As the nuts tighten, the Arms/Seals get pushed into the side of the Beam, causing them to foul and provide a stiff ride.

To solve this, we adapted this idea to use a straight bar, with rotating ends (EN24 Steel). With a central locking pin, this allows our rods to stay central, and rotate like OE Torsion Leaves would. This further allows you to run standard Grease Seals on your Arms. To ensure our product maintains accurate positioning, we cut the bar with a CNC Mill, which is accurate by 0.2mm. To further improve the design, we added Dual Lock Grub Nuts to each side of the rod, to add extra safety by reducing the amount of freeplay.

The Essentials

-

MOA430 Goldtops Ultimate Air Ride Front Shock / Sleeve Bag Struts, Pair

In StockSKU: 030010007£495.00inc 20% VAT1947-65 Beetle / Ghia Link Pin Bolt on Lower Shock Relocators

In StockSKU: 030030016£119.95inc 20% VAT1948-79 Beetle / Ghia “The Revolution” Cantilever Swing Axle / IRS Rear Air Ride ....

BackorderSKU: 030010057From £1,399.50