Instructions for Whiteband Trims – Read fully before fitting.

Suitability

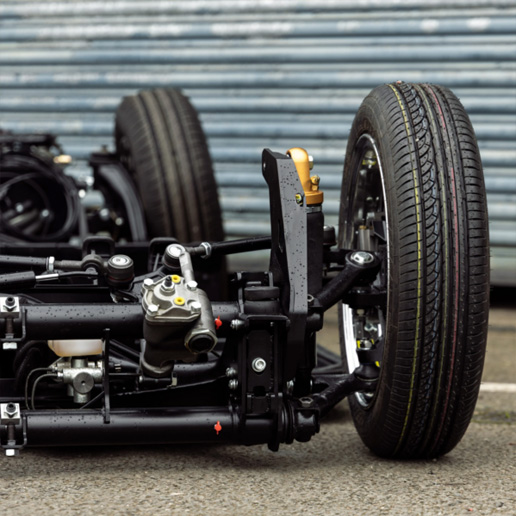

Trims can be fitted to any type of wheel-alloy, steel or wire. Where low-profile tires are fitted, there must be at least 3 inches (75mm) of sidewall for correct fitting. We recommend that new tyres are driven on first as being brought up to full operating temperature a few times helps sweat off the waxy mould release that new tyres are coated in.

Fitting

1. Remove the wheel from the vehicle and fully deflate the tire. The tire sidewall, especially underneath teh outer rim, should be thoroughly cleaned to remove any dirt or residue of tire bead lubricant. This is the best done with buffing solvent or something similar such as panel wipe or brake and clutch cleaner. DO NOT use methylated spirit, white spirit or turpentine as they are totally unsuitable for this purpose. Hot water, detergent and a scrubbing brush will also work but this takes a lot longer and needs more ‘elbow grease’!

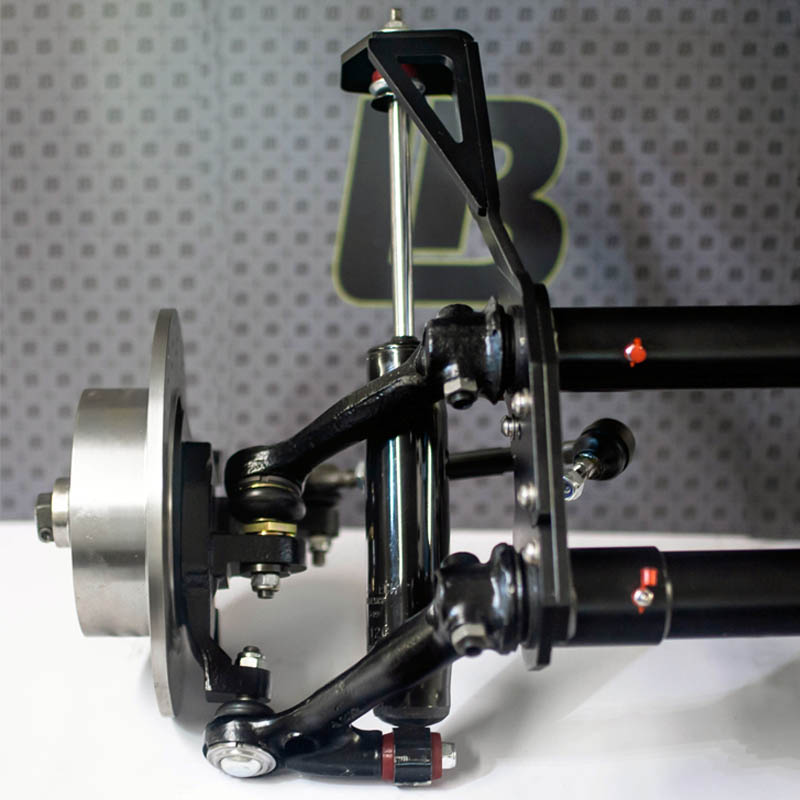

2: Place the wheel flat on a stable work surface. There is no need to push the bead off the rim but while pushing down on the sidewall with one hand, begin inserting the inner edge of the trim (seating lip) between the rim and the sidewall. Move around the rim repeating this until the seating lip is gripped all around the rim, taking care not to stretch or bunch the trim at all as you go.

3: Finish off by using a rubber mallet or your fist to tap the trim into the correct position, with none of the seating lip remaining visible. Inflate the tire to the normal pressure.

Common Fitting Problems

If the seating lip squeezes out from between the tire and the rim when the tire is inflated, contamination (most probably bead lubricant or mould release) is preventing the seating lip from getting any grip. The remedy is simple, repeat step 1 until the rubber is squeaky clean. Any shine on the rubber is a clear sign of this as clean rubber has a matt appearance. Remember to clean the seating lip before trying again as this may have become contaminated through contact.

If the trim has a bulge or is lifting away from the tire after fitting, it has not been centrally fitted. A bulge or ripple indicates that the trim is bunched at that point, while lifting is a sign that it is slightly stretched. To Remedy this, deflate again and either refit if the problem is substantial or if only minor, tap the trim with a rubber mallet trying to push the bulge around the wheel until it lies flat against the sidewall.

Maintenance

To prevent damage to the trims, avoid contact with the kerb. Damaged trims should be removed immediately as they may tear and become detached from the seating lip. To Clean use household detergent or a brillo pad (Fine steel wool & soap used for cleaning kitchen pots and pans). Once the trim has been correctly fitted and the tire inflated, pull back and apply rubber grease between the trim and sidewall. This prevents the generation of friction between these surfaces as the tire flexes during driving and applies particularly to radial tires. This grease should be checked and replenished on a REGULAR bases as failure to do so can cause chaffing on the sidewall and places excessive strain on the seating lip which may cause damage to the trim. DO NOT FIT AND FORGET AS REGULAR MAINTENANCE IS ESSENTIAL TO THE LIFE SPAN OF ALL PRODUCTS OF THIS TYPE. Castrol Red Rubber grease is recommended for this purpose.

Limebug will not be held accountable for any costs of fitting, or consequential expenditure or loss arising from the way in which the trims are fitted to the tire.

A great video here from Mooneyes that should help you with installation also,