Aircooled VW Serpentine Systems Explained and the why

Why Serpentine not Stock V Belt?

A common question we hear, the big reason is cooling and charging. Sounds strange to link a belt to do both those things but here is how. A stock V-belt drive uses a number of shims to maintain the tension of the pulley, however due to the narrow tall profile of the standard V-belt they are highly prone to slip and ‘lift off’ at high RPM’s.

How does that effect cooling and charging?

The alternator pulley is driven by the crank pulley, the shaft through the centre of the alternator also drives the cooling fan, an essential life and death component of an aircooled engine. When BHP is increased substantially the likelihood of liftoff and belt slip on a V-Belt approach almost certain.

What does the Serpentine belt system do to prevent lift off?

A serpentine system such as the MST systems we stock use a thin flat belt drive which is wide, it has several webs throughout the internal structure, and due to the wide thin nature, the height of the rubber element is reduced, which slows stretch, that twined with the wider profile means more surface area to grip. It’s like putting a low profile wide tyre on your car, this means less tyre wall slop, and more contact with the ground meaning more grip. So back to the serpentine system, this all adds up to a belt drive that can cope with higher performance engines and maintain cool running and continuous alternator charge delivery.

So why the tensioner?

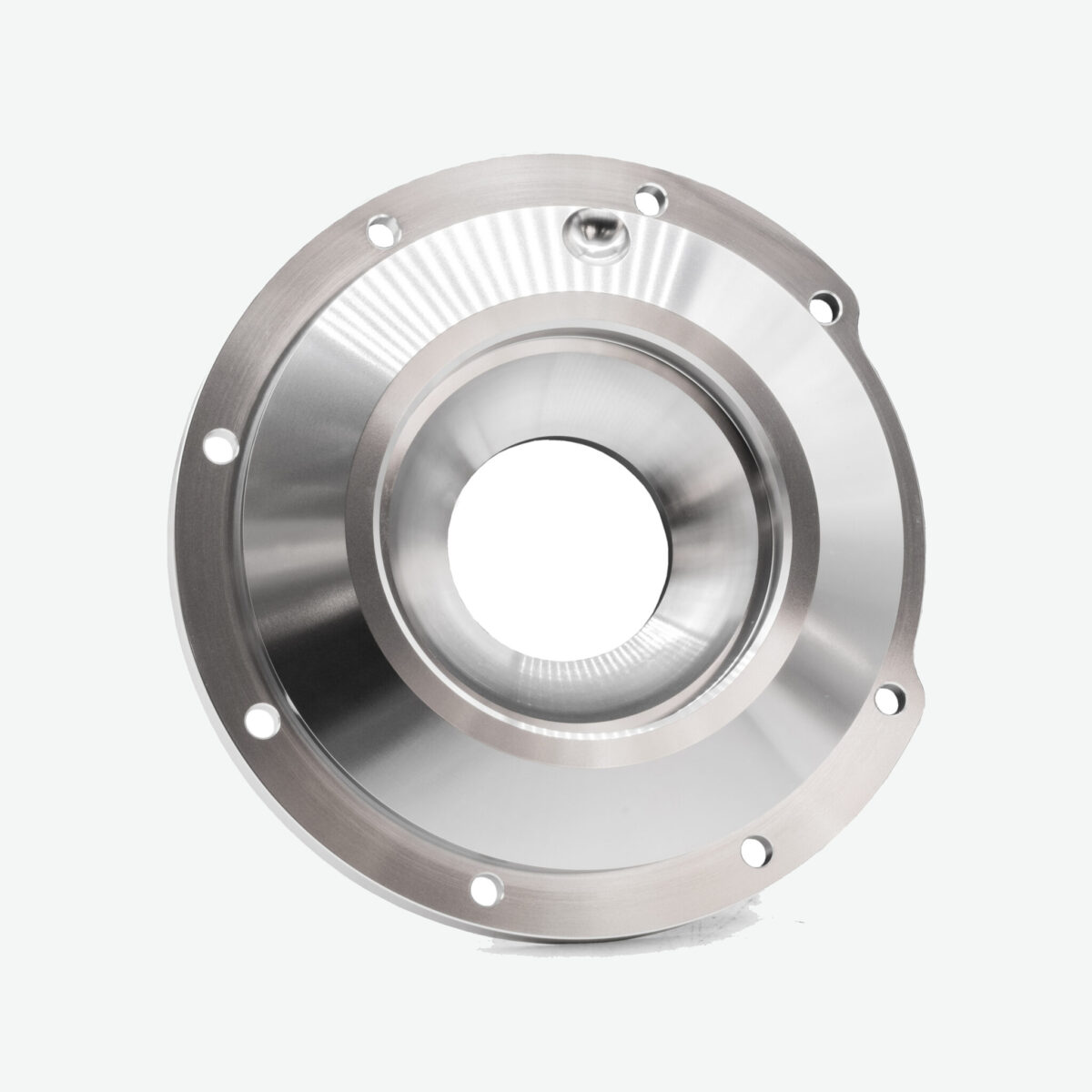

The tensioner is there in replacement to the original shims, same as with most modern engines, typically an element is movable to maintain good tension on the belt drive, normally the alternator/ water pump. However an aircooled engine does not have a water pump for obvious reasons and the alternator is fixed as is the crank position, hence the addition of the tensioner.