Type 3 / 34 4″ Narrowed Complete Lowering Kit

Classic Aircooled VW Complete Lowering Kits parts by Limebug

Looking to lower you Aircooled Volkswagen the right way? Look no further. The Limebug Complete Lowering Kit is the solution for taking a totally stock Type 3 including total narrowing of the front axle with the correct narrowed track rods, narrowed torsion leaves and then of course all of additional required components designed by our engineers here in the UK.

Please note: This system will require the following donor parts from a T1 Beetle or Ghia

– T1 Ball Joint Trailing Arms (Full Set)

– T1 Dropped Spindles (Suited to drums or disk at your preference)

– T1 Drag Link/Pitman Arm (Connects the Track rods to the steering Box)

– Trimming the lower leading edge on your front Frame head. (Note this not 100% neccesary, however you will more than likely damage/ bend them when driving the vehicle at lowered heights. These are the lowest element on the vehicle at the front by around 2″

What’s included in the kit?

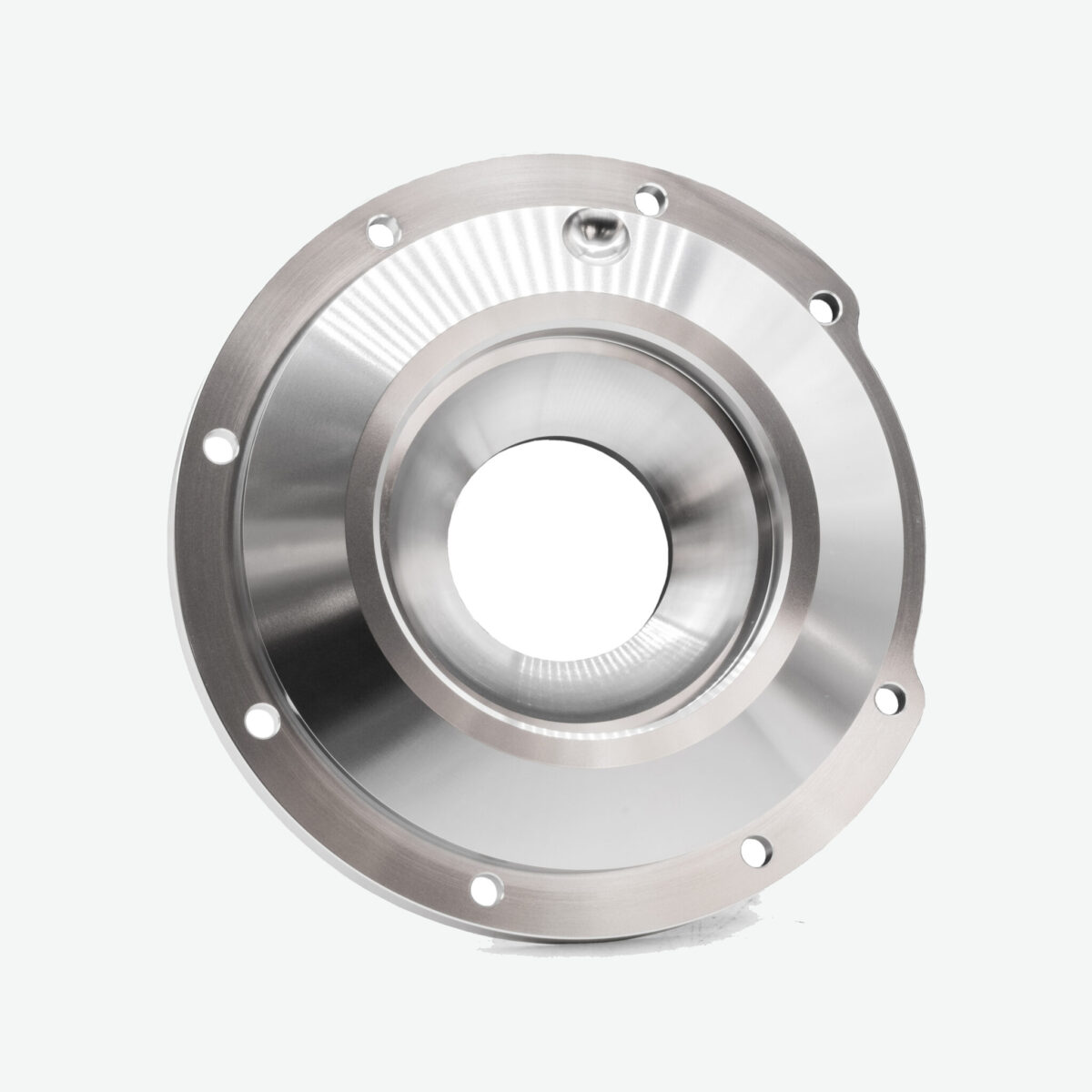

Type 3 / 34 4″ Narrowed Static Conversion Ball Joint Beam, Titan Series

Lets start this section with a deep dive into the controversial world of type 3 conversion beams.

Why do any of this and change my Type 3 Beam?

The simplest word to start this module with is limitations. The Type 3 platform albeit a step forward in luxury in terms of its principles presented a world of issues when it came to changing anything VW had already put out there. The type 3 front axle uses a floating beam within a rubber cushion to give a more luxurious feel. By this we mean predominantly soft ride with reduced noise within the cabin. The trade off of this is where things get a bit controversial, while no-one can deny it made it softer, I think it may be up for debate whether softer was really needed, as stock Beetles / Ghias were far from hard in the first place. The new platform brought forward some interesting ideas with crossed over torsions, a different style of ball joint, wider track, larger brakes etc. However You just can’t get a Stock type 3 very low, the structure of the front end uses indexed torsion bars to set the ride height, so you don’t have adjusters, the problem is with the width of a type 3 beam being fixed by these torsion bars, you cannot narrow the front end at all to fit tyres within the fenders as done with a Beetle. The second downfall is there is really no way to make a dropped spindle without cutting and welding and therefore increasing the track width further. This also means that as the ride height is lowered the harshness increases with the trailing arm angle.

So how does a Type 1 conversion beam help this on a Type 3?

Critical to spec’ing your beam, with complications and benefits to both RHD and LHD configurations, its key we get this piece of information to spec such elements as tie rod length, pitman steering arm and suitable steering stop. We can also assist you with best positions for steering box and damper mount once fitted, there are intereference points associated with certain aftermarket parts such as fuel tanks which require some specific adjustments in order to get maximum drivability from your new Fully Assembled Beam. But doesn’t this push my wheels back and make the front look weird? The answer would have used to be yes, the more DIY style beams use the main tubes and directly mount these to the frame head of a Type 3, this would push the wheels backward by around 20mm causing a range of issues with steering column position as well as looking odd We build in our unique castor adjuster into the beam here, whilst moving the axle tubes forward to marry up perfectly with Type 1 trailing arms, combined the wheel position in the arch is exactly as original Type 3.

Castor Adjustable Section, Why does only your beam have this? and what does it benefit in terms of drivability?

The type 3 drivability as a metric we decided to play around with the extra room and features the type 3 beam gave us. This opened up a small gap for a unique idea we had been playing with for a number of years. The Castor Adjuster… We are all familiar with the torsion leaf adjusters, but castor adjusters, why do that? As standard all Aircooled VW Car models run a few degrees of positive castor, this helps self centre the wheels when cruising and prevents bump steer. Our castor adjustable beams mimic the factory angle almost exactly giving you and almost identical driving experience in the neutral settings.

So why make it adjustable then?

The answer to this is simple, all old VW’s run with their front end higher than the rear as standard, and when nearly everybody lowers the vehicle typically the front receives a more excessive drop than the rear, this can be a combination of suspension and wheel/ tyre setup. So we developed an adjustable castor system. This allows you to run stock, or slightly + or – the Original postion, typically more nose down more postive castor, the flatter the vehicle the more negative the castor. By having this additional calibration the owner can tune bump steer along with ball joint travel limits to give their type 3 the absolute optimal ride quality, drivability and stance.

Tie Rods & Tie Rod Ends

High grade CDS turned seamless tubing is the foundation to building up our through rods, twinned with optional OE quality track rod ends and a hard wearing durable powder coat, this is the only sensible way to narrow your Type 3 Variant.

We also produce these track rods in a stock width, meaning when the track rod end wears out you are not stuck with having to throw away the long rod as factory ends are crimped into place.

These feature, German Quality Track Rod Ends, and UK manufactured Track Rods. All Rods are made to our Width guides, and suited to LHD or RHD appropriately.

2″ Dropped Adjustable Dropped Spring Plates (Please ensure you pick the correct style and spline length – please contact us for more information)

2″ Adjustable Dropped Rear spring plates for Type 3 Variants.

Each kit includes two adjustable spring plates and a pair of spacer plates to ensure the correct pinch on the rear, ensuring good lift / drop and smooth movement once desired ride height is set. These plates are simply adjusted using the easy access grub screw block fixed to the side of the spring plates – no need to completely disassemble the rear axle.

These spring plates are produced in house with our bespoke spline broach to ensure precision fitment to your torsion bars. The broached sections are then CNC Robot welded to the spring plate sections to ensure a consistent and precise production. The plates are then pre-blasted and finished in a smooth Satin Black powder coat.

Designed to also correct tow-in problems on the rear of your vehicle as each spring plate features slotted driveshaft mounting holes allowing the rear to be laser aligned, this dramatically reduces tyre wear and the loose/ skatey feel to the rear end found on stock spring plates.

Details:

– 2″ drop and then adjustable approx 4″ either side

– Trackable dropped plates

– Stress relieving spacers included

– Produced by us here in the UK

– Hardwearing Satin Black powder coat finish.

Combination of Urethane Spring Plate bushings to suit your new spring plates and rear suspension set-up.

Torsion Bar Urethane Grommets, 2″ Inner Diameter for Inner Fitment and 1 7/8″ Inner Diameter for Outer Fitment. Supplied in either Smooth or Knobbly style pairs to suit the suspension set-up.

The option of either GS340, GS380 or GS460 Shock Absorbers to suit a variety of vehicle ride heights.

GS380: MOA GS340 Gas-Charged Shock absorber with a minimum compressed length of 235mm, through to 340mm at their maximum expansion.

GS380: MOA GS380 Gas-Charged Shock absorber with a minimum compressed length of 255mm, through to 380mm at their maximum expansion.

GS460: MOA GS460 Gas-Charged Shock absorber with a minimum compressed length of 295mm, through to 460mm at their maximum expansion

Ultimate High Performance gas charged shock absorbers, providing both rapid rebound, reduced roll, yet with soft damping specifically for lowered aircooled VW models. The GS380 are one of the shorter shocks on the market, well suited to mildly lowered static vehicles.

With the option to also add:

Type 3 Bolt In Wheel Well

Bolt in wheel well, precision cut to direct fit in place of the bolt in wheel well found on all Notchback/ Fastback and Square back Type 3’s.

Direct swap this 2mm thick plate ensuring you won’t damage you will no longer have to scrape on speedbumps and essentially keep your vehicle water and wind tight.

SKU: 030050039