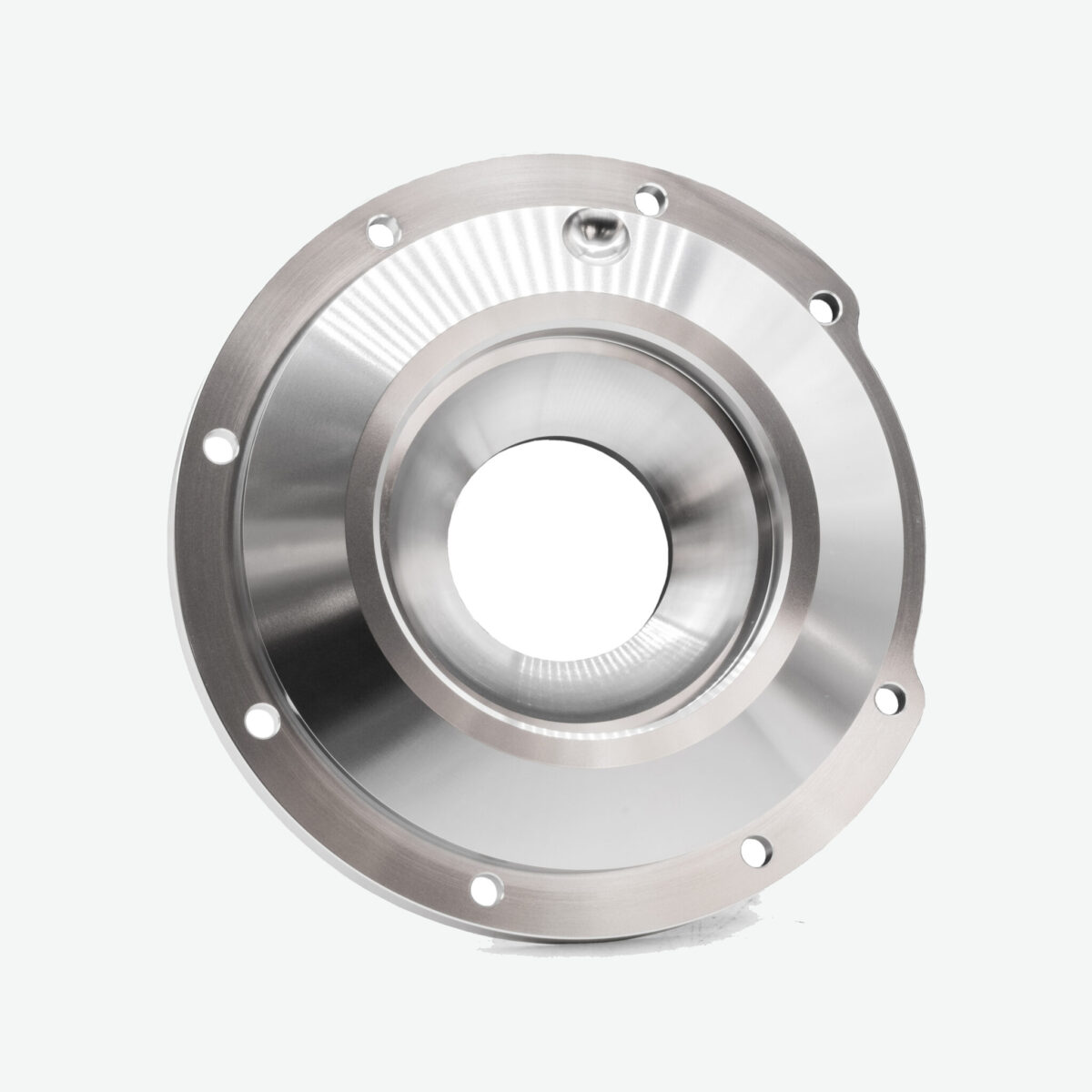

Type 3 / 34 4″ Narrowed Static Conversion Ball Joint Beam, Titan Elite Series

Classic Aircooled VW Type 3 Beams parts by Limebug

Introducing the Elite Series – Our Next-Level Beam Range

We're pleased to unveil our new and improved Elite Series, now available across all platforms. Each beam is engineered for precision and durability, and is supplied with OEM-style bearings to ensure optimum trailing arm fitment, whilst matching the exact specifications of the original.

Let’s start with a deep dive into the controversial world of Type 3 conversion beams

Why change my Type 3 beam at all?

In a word: limitations.

The Type 3 platform, while a step forward in comfort and refinement compared to earlier models, brought with it a range of challenges for anyone wanting to modify the suspension. The Type 3 front axle uses a floating beam housed in a rubber cushion, giving a softer ride and reduced cabin noise. While this setup undoubtedly improves comfort, there’s debate over whether it was necessary—after all, a stock Beetle or Karmann Ghia was hardly uncomfortable to begin with.

This new platform introduced some interesting features: crossed torsion bars, a different style of ball joint, a wider track, and larger brakes. However, it came with a major drawback—you simply can’t get a stock Type 3 very low. The ride height is set by indexed torsion bars, so there are no adjusters. Because the torsion bars also fix the beam width, you can’t narrow the front end to tuck the tyres under the wings as you can with a Beetle.

The second challenge is that making a dropped spindle for a Type 3 requires cutting and welding, which increases the track width even further. And as the ride height is lowered, the trailing arm angle becomes steeper, making the ride harsher.

So how does a Type 1 conversion beam help a Type 3?

Specifying your beam correctly is crucial—particularly as RHD and LHD setups each have their own quirks. We use your vehicle details to ensure correct tie rod length, pitman arm compatibility, and the right steering stop position. We can also guide you on the ideal mounting positions for the steering box and damper, taking into account possible interference from aftermarket parts such as larger fuel tanks.

One common concern is whether a conversion beam pushes the wheels backwards, ruining the stance. With many DIY-style beams, that’s true—the axle tubes are mounted directly to the Type 3 frame head, moving the wheels back around 20 mm and causing steering column misalignment as well as a less-than-ideal look. Our beams solve this with a built-in caster adjuster and revised axle tube positioning, perfectly matching Type 1 trailing arms so the wheel sits exactly where it should—just like on the original Type 3.

Caster Adjustable Section – Why only on our beams, and how does it improve drivability?

The Type 3 beam design gave us the opportunity to experiment with an idea we’d been developing for years: a caster adjuster. We’re all familiar with torsion leaf adjusters, but caster adjustment is far less common.

From the factory, all air-cooled VW models run a few degrees of positive caster, which helps the wheels self-centre at cruising speed and reduces bump steer. Our beams replicate the factory angle almost exactly in the neutral position, giving a driving feel very close to stock.

So why make caster adjustable at all?

The answer is simple: most classic VWs sit with the front higher than the rear as standard, and when owners lower their cars, the front is often dropped more aggressively than the rear. This change in stance alters the caster angle—more “nose down” typically increases positive caster, while a flatter stance reduces it.

Our adjustable caster system allows you to fine-tune this angle—slightly positive, slightly negative, or stock—depending on your suspension setup and stance. This means you can minimise bump steer, keep ball joint travel within limits, and achieve the perfect combination of ride quality, drivability, and stance for your Type 3.

SKU: 030020047