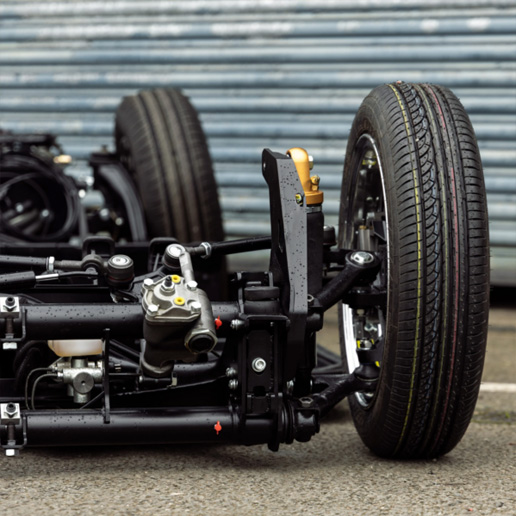

Traditionally raising the transmission is carried out to prevent high camber which causes premature wear of both rear wheel bearings and gearbox fulcrum plates. These high running angles reduce the transmission oil flow to the gearbox side of the axle starving the wheel bearings of lubrication. Typically the fulcrum plates will begin knocking due to continuous movement as the axle rotates.

When lifting or raising the transmission the amount of camber will decrease, this will reduce stress on all the fore mentioned components, an additional benefit of this is reducing tyre wear and increasing tyre-road contact.

When should I raise my gearbox, and by how much?

Depending on the style of vehicle different degree of raise may be required, typically tyre size and ride height are the primary driving factors, the larger the overall rolling radius, usually the higher the raise we would recommend.

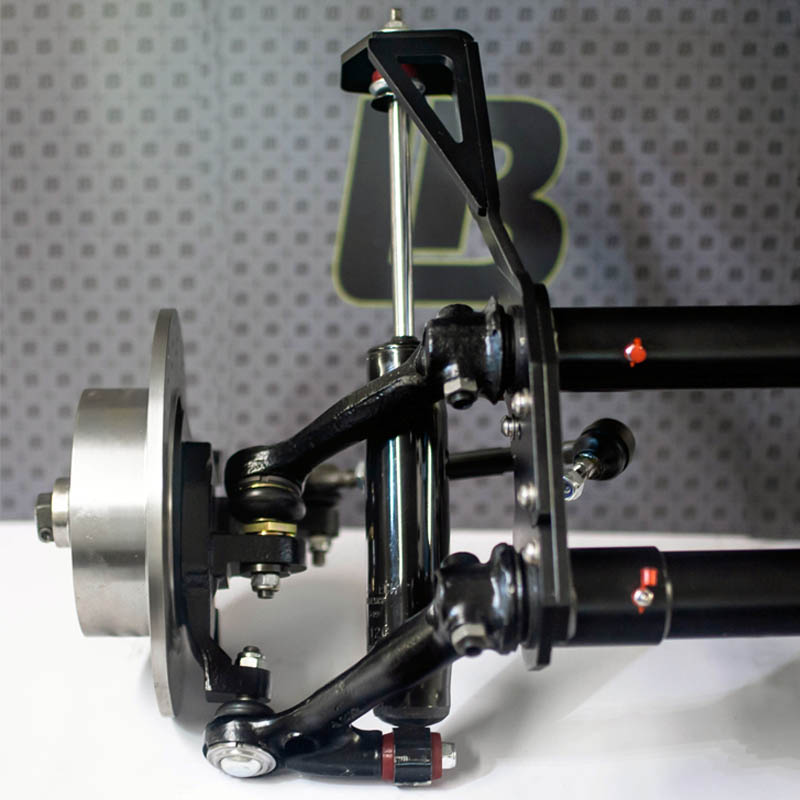

Our transmission cradle is totally unique in its design encompassing the ability to run at stock height, 0.5” raise and 1” raise in one product.

Using the system is simple, requiring only a jack, 13mm spanner’s and the main Cradle bolt (usually 27mm), no access is required to the bell housing once first installed.

Our new design consists of high resonance bushes which provide fantastic absorption of transmission noise and vibration, ensuring the drive of the vehicle to feel just as good as using OEM mounts even with the transmission raised.

The mount also utilises special polymer bush which will not de-laminate against metal as it is mechanically fixed to the chassis rather than relying on glue to hold the engine in place. The bushes are also oil/fuel resistant increasing the longevity of your product.

Compatible with: Type 1 Beetle / Type 14 Karmann Ghia and Type 3 models 1950-79 and T2 Split Screen models (All Years).

Why Change from the standard Gearbox Mounts?

Listed below some of the most common Stock Gearbox / Trans Mount flaws:

- Delaminating Bushes – Usually a knock when changing gear can be felt or applying or releasing the throttle, this is most commonly attributed to the glue/ rubber coming away from the metal of the rear gearbox mount.

- Mis-aligned Frame Horns – Often causing cross-threading of the main Gearbox Bolts, nearly all chassis frame horns are slightly mis-aligned.

- Prematurely worn Fulcrums on extremely low vehicles. This is caused driving with high rear wheel camber angles.

- Solid mount solutions can cause heavy transmission noise and vibration.

- Reduced ground clearance when lowering the vehicle, causing damage to the undercarriage.

Please note: Some clearance modifications may be needed when raising 1″, 0.5″ requires minimal adjustments. We find typically the tailpipe tips may just need bending down slightly to clear the valance if in the OE position.

SKU: 020040005